Renaissance to Eighteenth-century Accounts of Papermaking

“... and what is the use of a book,” thought Alice, “without pictures or conversations”.

Lewis Carroll, Alice’s Adventures in Wonderland (1865)

Probably the worst way there is to discover the most important thing done in any historic period is to take the word of that period for it. What to the generation of its occurrence is merely a casual happening, an amusing toy, or an impractical intellectual or physical adventure, in time frequently becomes all-important for the world.

William M. Ivins, Prints and Visual Communication (1953)

Descriptions of the papermaking process have appeared various times over the centuries and are a prime source of information, especially when they are accompanied by images. Rather perplexingly on the other hand, there is no one work that brings these texts together, with due commentary, interpretation, and bibliography. In particular the very early descriptions, albeit brief, are at times difficult to find in more recent published sources and so, although the present work is intended primarily as a bibliographical helpmeet, as a concession to vox populi, the texts of Bartolo da Sassoferrato, Francesco Maria Grapaldo, and Angelo Rocca are duly transcribed. While the Seventeenth century account by Giovanni Domenico Peri is a pleasing exception, since it is available in an high quality, scholarly edition, there is no proper modern edition of the French text of Lalande, though strangely the Italian, English, and German translations, that appeared almost immediately, have all been republished in modern times, and a similar absence is true for the paper-related entries in the Encyclopédie, which went through a complicated evolution [5].

In his treatise De insignis et armis the Fourteenth-century Italian jurist, Bartolo da Sassoferrato (1314-57), famously talks about brands or griffes in surprisingly modern fashion and gives the watermarking of paper at Fabriano as an example:

Quedam vero sunt signa cuiusdam artificii seu peritie. Et hic advertendum, quandoque sunt signa artificii in quo principaliter operatur qualitas loci. Exemplum: in marchia Anchonitana est quoddam castrum nobile cuius nomen est Fabrianum, ubi artificium faciendi cartas de papiro principaliter viget, ibique sunt edificia multa ad hoc et ex quibusdam edificiis meliores carte proveniunt, licet ibi faciat multum bonitas operantis. Et, ut videmus, quodlibet folium carte suum habet signum propter quod significatur cuius edificii est carta. Dico ergo, quod isto casu apud illum remanebit signum apud quem remanebit edificium in quo fit, sive iure proprietatis, sive iure conductionis, sive quovis alio titulo, sive in totum, sive in partem, sive etiam mala fide teneat, toto tempore quo tenet non potest prohiberi uti signo, sicut in ceteris iuribus realibusTranslation:Some trade marks are proper to a particular craft or skill, and here it should be noted that sometimes they are connected to the nature of the place in which the product is chiefly made. For example, in the March of Ancona, there is a certain noble city called Fabriano, where the manufacture of paper is the main business. Here there are many paper mills, and some of them produce better paper, although even here the skill of the worker is of considerable importance. And here each sheet of paper has its own watermark by which one can recognize the paper mill. Therefore, in this case the watermark should belong to the one to whom the mill itself belongs, no matter whether it remains in his possession by right of ownership or lease, or by any other title, wholly or in part, or even in bad faith. During the entire time in which he has possession of the mill, he cannot be prohibited from using the watermark, as with other rights to immovable property [5].

Although one hates to embarrass or contradict such an eminent Medieval jurist, he just happens to be wrong! Very early watermarks might well have been a means of identifying the maker of the paper, since signs such as the Greek cross have much in common with the marks employed by the wool merchants to identify their bales. By the middle of the Fourteenth century, or the period when Bartolo was writing, rather than signify individual makers or mills, watermarks had transformed themselves into symbols denoting types of paper. Unfortunately the symbolism for the most part today appears as an only partially-understood Linear B, as Briquet and other repertories make all too clear.

In his large volume De partibus aedium, published in Parma, probably in 1494, better known perhaps for its references to cheese and wine making, the humanist Francesco Maria Grapaldo, after a disquisition on book practices in the ancient world, introduces a contemporary first-hand account of papermaking, as he had perhaps seen it practiced in the paper mills in the hills above Parma:

Apud nos hodie charta e lineis canabinisque pannis veteribus et attritis producitur. Secti in frustula aqua inspersa per dies xi macerantur et in pila aquaria pilis ferratis minutim contusi addita calce in alteram transferuntur. Exemptos deinde in aquaria tinia cum posuerint formis aquam transmittentibus in singula extrahunt folia, quae laneis pannis alternatim commixtis proelo calcantur aedificioque ad id patulo prius siccata [>siccantur]. Mox glutino facto ex pellium quisquiliis sive ramentis, quae coriarii et membranarii reponunt ad hunc usum fervefactis intincta. Rursus siccata et vitro levigata aptissima redduntur ad tolerandos calamos: et atramentum non transmittendum. In hoc Parmenses chartae sibi principatum vendicarunt, cum in candore prae caeteris Fabrianae commendentur. Prima enim chartae datur adorea: si non est bibula et atramentum non sorbet, quod si fuerit siccandae scripturae, ne fiant liturae erit utilis.Translation: Nowadays we make paper from old and worn out rags of linen and hemp. These are cut into pieces, water is poured over them, and they are left to soak for eleven days, after which they are transferred into vats filled with water and, with the addition of lime, pounded into pulp with iron mortars. Next they are removed and placed in a vat of water, in which the workers dip frames that allow water to pass through and so draw out the individual sheets. These they interleave with felts and squeeze in a press. After they are dried in a spacious building specially designed for it, they are dipped in hot glue made from the fragments and scraps which tanners and parchment makers set aside for the purpose. After being dried again, they are calendared with a piece of glass, so they will take writing and not let the ink through. In this respect Parma paper is reckoned to be the best, while Fabriano paper is highly praised for its whiteness. It is held to be a prime quality in paper that it is not absorbent and does not soak up the ink—yet if it does, it will still be useful for drying the handwriting so as to avoid blots.

This passage is followed by remarks about sheet sizes and names, in which, after the Augustan and Claudian sizes in the classical era, he notes that “imperialis” and “regalis” are characteristic of Bologna and adds remarks about paper made for wrapping purposes, as follows:

Vilior est emporetica, quae inutilis scribendo involucre segestrium vice mercibus praebet, et ideo a mercatoribus cognominata. Graece enim emporos mercator et emporium locus mercatus et nundinationis ad quem distrahendi praestinandique causa conveniunt mercatores. Chartaceum involucrum cucullum dicemus et venditorem chartarum chartularium nos, graeci chartopolin.Translation: a cheaper sort is emporetica, which is no good for writing on, but in the manner of a straw wrapper provides covering for goods, hence its name. For in Greek a merchant is known as an emporos and an emporium is the market place where things are traded, to which merchants go to buy and sell goods. We shall call a paper wrapper a cucullus or ‘hood’, and the seller of paper a chartularius in Latin, in Greek a chartopola.

Although the text was republished five times during the Sixteenth century, with variants, there is no modern edition [5].

A recent and extremely interesting discovery is a manuscript sketch by Italian artist, Alberto Alberti (1526-98), military architect, sculptor and engraver, attributed to c. 1558-65, in the collections of the Canadian Centre for Architecture in Montreal. It shows a traditional stamping mill, with considerable accuracy, and includes notes about the technical features of the machine [5].

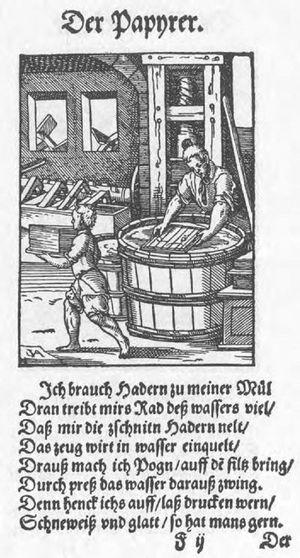

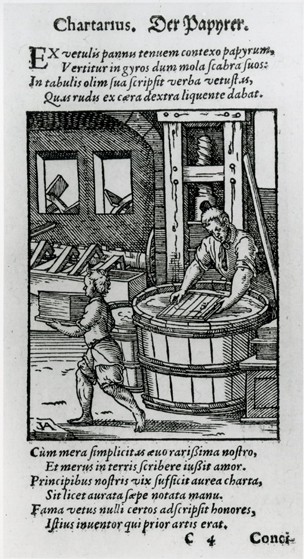

The first example in history of a picture book, also known as the ‘Book of trades’, where two separate texts are modelled around the same set of 115 woodcut images, showing the professions of the time, was conceived by the Swiss-German artist and sometimes xylographer, Jost Amman (1539-91), who signs it with his monogram in the lower left-hand corner [Figures 1-2].

Figure 1. Jost Amman, “Der Papyrer”, in Hans Sachs, Eygentliche Beschreibung aller Stände auff Erden, hoher und nidriger, geistlicher und weltlicher, aller Künsten, Handwercken und Händeln, Franckfurt am Mayn, bey Georg Raben in Verlegung Sigmund Feyerabents,1568, f. F2r. Image by courtesy of Wikisource.

Figure 2. Jost Amman, “Chartarius. Der Papyrer”, in Hartmann Schopper, Panoplia. Omnium illiberalium mechanicarum aut sedentarium artium genera continens, Francoforti ad Moenum, apud Georgium Coruinum, impensis Sigismundi Feyerabent, 1568, f. C4r. Image by courtesy of The British Museum.

The image enjoys celebrity status, and no bibliography could begin to enumerate the times it has been reproduced in writings about paper and elsewhere. As a depiction, however, it contains some massive inaccuracies, interestingly compared to the related activities such as typecasting or printing, evidently drawn from life, where it is difficult to fault Amman’s depiction. Paper mills, however, were found out of town and were not necessarily easy to reach, especially for an artist based in Nuremberg. The scene therefore appears to have been drawn from memory, or from a very rough preliminary sketch, and betrays a limited understanding of the process: for instance, the waterwheels (why have two?) outside the windows cannot connect up to the trunk of the stamping machine, while the stamps themselves – which look like the legs of a creature from a sci-fi movie – have no connection with the multiple basins, shown however as a single trough, in which the rags are beaten; the threads of the screw on the large press against the wall turn the wrong way; the vat is only just large enough to get the mould in; the vatman is holding the mould at the centre of the long sides, instead of the short sides, and what presumably are intended as chainlines are parallel to the same long side, when they should be parallel to the short side; part of a post is visible, although it should be covered by the barrier which normally protects the feet of the coucher from falling water; on the other hand, no coucher is visible, though he might be just off screen; the young boy strolling across in front of the vat may be carrying a freshly-made post, which would be too heavy to lift in such a nonchalant fashion (if on the other hand the paper is dry, it has no business being in this part of the factory); and so on and so forth. The work was first published in Frankfurt in 1568 in parallel versions, the first in German with the title Eygentliche Beschreibung aller Stände auff Erden.

The image of the papermaker “Der Papyrer” is accompanied by verses in German by Hans Sachs (1494-1576) reading:

Ich brauch Hadern zu meiner Mül, Dran treibt mirs Rad deß wassers viel Daß mir die zschnitn Hadern nelt Das zeug wirt in wasser einquelt Drauß mach ich Pogn, auff den filtz bring Durch preß das wasser darauß zwing. Denn henck ichs auff, laß drucken wern Schneweiß vnd glatt, so hat mans gern.Translation: I need rags for my mill. The mill churns through lots of water, so the cut-up rags are beaten. The stuff is full of water. I make sheets out of it and put them on the felts. Using a press I squeeze the water out, then I hang them up and let them dry. Snow-white and smooth, that is how we want it to be.

In the Latin version by Hartmann Schopper (1542-c. 1598), entitled Πανοπλία. Omnium illiberalium mechanicarum aut sedentariarum artium genera continens, the text for the “Chartarius/Der Papyrer” becomes:

Ex vetulis pannis tenuem contexo papyrum Vertitur in gyros dum mola scabra suos: In tabulis olim sua scripsit verba vetustas, Quas rudis ex caera dextra liquente dabat. Cùm mera simplicitas aeuo rarissima nostro, Et merus in terris scribere iussit amor. Principibus nostris vix sufficit aurea charta, Sit licet aurata saepe notata manu. Fama vetus nulli certos adscripsit honores, Istius inuentor qui prior artis erat.Translation: From old rags I weave my thin paper, as the rough millstone turns round in circles. Antiquity once wrote its words on tablets, which an unskilled hand formed from liquid wax, though sheer simplicity (rare among us nowadays) and sheer love had people writing in earth. For our princes gilded paper scarce suffices, though it be often inscribed with golden hand. Ancient report gave no one any definite credit as the first inventor of this art.

Hardly epic verse!

In his famous Theatre des instrumens mathematiques & mechaniques or Theatrum instrumentorum et machinarum, according to the issue, published at Lyon by Barthélemy Vincent in 1578, Jacques Besson, includes a copperplate illustration of a hand-activated beating machine. According to the didascalium, among the possible materials that can be pounded therein is paper, i.e. “Noua moletrinae trusatieis structura, ad premendos, et parandos pannos, et chartam, et terenda aromata, et comminuenda saxa metallis gravida …”. Given the much greater efficiency of a water-powered wheel and stampers, it is unlikely that this device, if ever constructed, had any real application in the paper industry.

One writer, who had an exceptional chance to produce what might have been a first-hand account of the papermaking process, was Tommaso Garzoni (1549-89), whose La piazza universale di tutte le professioni del mondo, first published in Venice in 1585, in some ways is a precursor of the Encyclopédie, consisting in an attempt to describe in detail the contemporary industries and manufacturing procedures. On the other hand he has evidently not been near a paper mill and has no idea what the process consists in, so the four pages he dedicates to paper are largely waffle and an opportunity wasted. The only element of interest is a brief mention of paper types and sizes, which he obviously obtained from a shop in town:

Et finalmente la carta o buona, o rea, o picciola, o commune, o mezzana, o reale, o imperiale, o papale, o da strazzo, o succhia, o capretta, o cartone, o fabriana, o ferrarese, o d’altri paesi.Translation: and finally the paper of good or inferior quality, or small, or standard, or Median, or Royal, or Imperial, or Papal, or for wrapping, or blotting, or as parchment, or card, or from Fabriano, or from Ferrara, or from other places.

The first successful commercial paper mill in Britain, established at Dartford in Kent in 1588 by German-born Thomas Spilman (or Spielmann) was celebrated in doggerel by poetic hack, Thomas Churchyard (c. 1520-1604). Just as a sample, here is his description of the papermaking process:

The Hammers thump and make so loud a noise, As fuller doth that beats his woollen cloth In open show, then Sundry secret toyes Make rotten rags to yield a thickened froth. There it is stamped and washed as white as snow. Then flung on frame and hanged to dry, I trow. Thus paper straight it is to write upon, As it were rubbed and smoothed with slicking stone.Hardly exalting as a technical description of the process, and absolutely dreadful poetry!

Just under a century after Grapallo, another brief sketch of the papermaking industry was published by bishop Angelo Rocca, founder of the Angelica Library in Rome, who in his history of the Vatican Library published in 1591 has this interesting excursus:

Reliquum est, vt de charta, qua hodie omnes fere vti solent, sermonem habeamus. Haec ex linteolis contritis multiplex fieri solet iuxta varias telarum species, quarum vna prætenuis, altera minus, tertia rudior, aut crassior, quarta vero crassissima, quam Latini vocant telam cannabaceam, filo admodum raro, & rudi contextam, Italice cannauaccia: ex ijs tribus fiunt chartæ ad scribendum, & ad imprimendum optimæ: ex quarta specie iuxta varium telarum colorem fit charta bibula & emporetica, quæ mercium involucris deseruit. Fit autem charta ex telis in frusta secatis, & in mortario ligneo, interiori tamen atque inferiori parte mortarij ferro cooperta, ferroque pistillo contritis: quæ quidem prius quindecim dierum spatio in aqua marcescunt, deinde dum teruntur, perpulchro sane artificio, lauantur, atque ita, vt fluxibilitate, & albedine lacteum repræsentent colorem. Postquam vero huius generis massa quattuor ac viginti horarum interuallo contrita in materiam subtilem ac fluidam redacta est, illa eadem super forma, siue, vt aiunt, modulo filis aeneis iuxta latitudinem, longitudinem, & profunditatem folij, quod faciundum curatur, confecto, extenditur, deinde ipsum chartæ folium ad aerem exsiccatur. Vbi vero exsiccatum est, in aquam, in qua excocta sunt pellium bouillarum residua, siue nerui, immittitur, & statim inde, ex aqua scilicet illa, hoc est glutino extrahitur, & ad aerem iterum exsiccatur, exsiccatumque super tabula lapidea, frusto marmoris fricatur, & expolitur: atque hunc in modum charta suam ipsius recepit perfectionem. Chartariæ officinæ in Europa multæ sunt; sed Italia alijs præstantiores habere existimatur. Quæ autem sunt in Fabriano, & chartarum copia, necnon præstantia ceteras excellunt officinas: in ijs enim omnia chartarum genera, & optima quidem conficiuntur, præsertim vero tres chartarum species, Papalis scilicet, Imperialis, & Regalis, quæ non nisi eo in oppido confici solent. Quamuis autem charta ex omni genere, maxime omnium continens atramentum, ne effluat, Fabriani conficiatur: Fulginea tamen paginula tantae est præstantiæ, vt nulla alia cum haec conferri queat. Multæ aliæ in Italia chartariæ extant officinæ, quæ breuitatis causa subticentur. Sunt autem in ora Salonina officinæ insignes circiter viginti, quarum charta est ad imprimendum optima, sed non satis alba. Extra Italiam Lugduni in Francia, Francofurti in Germania, & alibi chartæ conficiuntur…[5]Translation: It remains for us to say something about the paper that pretty much everyone uses on a daily basis. This is generally made from pulped linen rags in various grades corresponding to the various types of cloth. The first is extremely fine, the second less so, the third rougher or thicker, and the fourth very thick indeed. This last is called tela cannabacea or hemp weave in Latin, cannavaccia in Italian, a weave made up of very few and coarse fibres. The first three types produce paper which is excellent for both writing and printing; depending on the colour of the cloth, from the fourth is made blotting paper or wrapping paper, suitable for covering goods. Paper is made from cloth cut into pieces and put into a wooden trough, the inside and base of which are lined with metal, and then broken up with an iron pestle. The rags have been previously been allowed to soak in water for fifteen days, and then - this is the ingenious part - they are watered as they are being broken up, so that they liquefy and turn milk white in colour. After twenty-four hours of being beaten in the trough, the raw material is reduced to a smooth liquid. It is then spread out on a forme or “mould”, as they call it, made of copper wires to the same width, length, and depth of the sheet of paper that it is desired to make. The sheets of paper are then dried in the open air. When they are dry, the sheets are dipped again in water, in which the leftovers of hides and sinews of cattle have been boiled, and at once taken out of the liquid, or rather glue, and left out again to dry. After more drying, they are put on a stone surface and rubbed and polished with a piece of marble. In this way the paper is finished off. There are many papermaking factories in Europe, but the best are held to be those in Italy. The ones in Fabriano in particular surpass the other centres in quality as well as quantity of paper made. There they make all sorts of paper, and of all grades of quality, especially three varieties, Papal, Imperial, and Royal, which are only made in that one place. Though paper of every sort is made at Fabriano, and it is the best of all at taking ink and not letting it run, yet the small paper made at Foligno is of the very highest quality and no other can match it. There are many other papermaking factories in Italy, which cannot be mentioned for reasons of space. Some twenty well-known factories are found on Lake Garda, whose paper is fine for printing, though it is not white enough. Outside Italy paper is made at Lyon in France, Frankfurt in Germany, and elsewhere.

The contemporary interest in machinery and in the workings of machinery inspire the description of the stamping machine in the Nouo teatro di machine et edificii per uarie et sicure operationi con le loro figure tagliate in rame et la dichiaratione e dimostratione di ciascuna. Opera necessaria ad architetti, et a quelli, che di tale studio si dilettano, posthumously published by the Padua city architect, Vittorio Zonca (1568-1602), in the same city in 1607. Importantly, the account also includes a copperplate illustration, showing the interior of a papermaking mill, described as a “Cartiera overo Pistogio che pesta le strazze per far la carta”. The brief accompanying text is however largely uninformative.

The first extensive Chinese account of papermaking, including woodcut illustrations of the process, is published by Sung Ying-Hsing, Thien Kung Kai Wu [The Exploitation of the Works of Nature] in 1637. In his account the raw material, comprising bamboo shoots, is soaked for more than a hundred days, after which it is boiled in a vat for a further week or so. After further washing and rotting, the fibres are suspended in a vat and sheets of paper are made with a dip mould. Since the mix includes a resin or gum, sheets are couched onto a flat surface without interleaving with other material and are dried on a heated wall.

The city of Amsterdam has a tradition of gablestones showing the commercial and mercantile activities conducted in the building. One such, on a house built in 1649 for merchant Pieter van Haack, shows the interior of a papermaking factory and is arranged in two tiers: on the upper floor sheets of paper are hanging up to dry and rags are being sorted; on the lower floor, paper is separated from the felts after pressing, two men work at the vat, and a waterwheel turns a traditional stamping mill. The house was demolished in 1908 and the stone was placed in the Academy of Fine Arts. A modern replica can be seen at the corner of Keizersgracht and Leliegracht.

Half a century after Zonca, a Genoese scholar, Giovanni Domenico Peri (c. 1590-1666), not to be confused with the earlier Tuscan poet from Archidosso, born in the same year as Shakespeare, published a lengthy volume entitled I frutti d’albaro, Genova, Giovanni Maria Farroni, 1651, in which he dedicated several pages to a description of the papermaking process. This account is the most accurate and detailed account of the papermaking process previous to Lalande, although the text contains quite a few dialect terms and is anything but straightforward. Fortunately, it was edited and translated in 2003 by Conor Fahy [5].

The Orbis sensualium pictus by Czech writer and teacher, Jan Amos Komenský, latinized as Johann Amos Comenius (1592-1670), published in Nuremberg in 1658, is rightly celebrated as the first picture book for children. The first edition was bilingual, German and Latin; it was followed in 1659 by an English-Latin version translated by Charles Hoole, and before long was succeeded by polyglot versions in up to four languages. It was an enormous bestseller and went through numerous editions all over Europe, of which a fair number have probably not survived. In the sequence several images and texts are dedicated to the arts of the book, in the order ‘Ars scriptoria’, ‘Papyrus’, ‘Typographia’, ‘Bibliopolium’, ‘Bibliopegus’, and ‘Liber’. The images are simplistic, but effective, and were obviously cut in many different versions. The papermaking factory (n. 92 in most editions, but the numbering can vary) shows the vatman and the coucher working together; in a next door room sheets of paper are hanging to dry over bales of paper; and on the floor below is a stamping machine. Alternative, later versions of the woodcut also show the hydraulic wheel outside the mill.

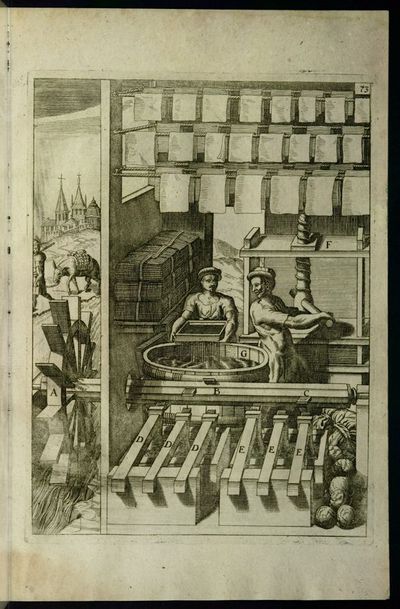

Georg Andreas Böckler (ca. 1617-1687) was a hydraulic engineer from Nuremberg, and his Theatrum Machinarum Novum, published for the first time in Nuremberg in 1661, was primarily dedicated to water-driven machinery, including a contemporary papermill [Figure 3].

Figure 3: Georg Andreas Böckler, Theatrum Machinarum Novum, neu-vermehrter Schauplatz der mechanischen Künsten, handelt von allerhand Wasser-Wind-Ross-Gewicht- und Hand-Mühlen, wie dieselbige zu dem Frucht-Mahlen, Papyr- Pulver- Stampff-Segen- Bohren- Walcken-Mangen, und der gleichen anzuordnen, Nürnberg, in Verlegung Paulus Fürsten, gedruckt bey Christoff Gerhard, 1661.

Although many of the details in the copperplate image showing a papermill are interesting, it contains several inaccuracies, some obviously due to the desire to compact into the same picture operations that would actually take place in different rooms and on different floors of the same building. It should be noted, however, that the mould being held by the vatman looks more like a baking tray (square rather than rectangular), and that, instead of holding it lightly but firmly in the middle of the short sides, he is clutching it to his chest; that the coucher, rather than handing back the twin mould is pulling on the press, where the screw turns the wrong way, while the post under the press is implausibly large; that the struts on the rotating trunk cannot reach the heads of the beaters; and that the sheets of paper, hung over the workmen’s heads rather than in the attic, seem more suited to wallpaper than to the invariant rectangle.

Elias Porzel, latinised as Porzelius or Porcelius (1662-1722), included in his collection of images Curioser Spiegel, in welchem der allgemeine Lauff des ganzen menschlichen Lebens... vorgestellt wird, published in Nuremberg in 1689, reprinted in 1812 and 1824, easily the most accurate depiction of the inside of a papermill previous to the Encyclopédie [Figure 4]. In fact, no criticism can be made of it.

Figure 4. Elias Porzelius, “Das wohlausgesonnene Pappiermachen”, in Curioser Spiegel, in welchem der allgemeine Lauff des ganzen menschlichen Lebens... vorgestellt wird, Nürnberg, verlegt bei Johann Endter, 1689. Image by courtesy of the Objektkatalog der Sammlungen des Germanischen Nationalmuseums.

In 1693, a Jesuit priest, Jean Imberdis, celebrated the papermaking industry of his home town, Ambert, in the Auvergne, by publishing at Clermont-Ferrand a Latin poem in 486 hexameters, based on Vergil’s Georgica. As Don Marquis once said, publishing a book of poems is like dropping a rose petal into the Grand Canyon and waiting for the echo: this example made even less noise, until the Nineteenth century, when a single surviving copy was rediscovered. It has, however, been republished and translated into French, German, and English, which fortunately makes reading a bit less hard.

The prize for the first ever book entirely about paper goes to the Ferrara doctor and lecturer in law, Francesco Maria Nigrisoli (1648-1727), whose De charta ejusque usu apud antiquos, was published in Venice by Girolamo Albrizzi in 1699. Unfortunately that is its only merit. In terms of content, apart from a very brief explanation of the papermaking process, it is just academic waffle.

The Eighteenth century of course provides us with several accounts of papermaking, some of them magnificently illustrated that have dominated all subsequent discussions. The first is the Cyclopædia, or, An Universal Dictionary of Arts and Sciences by Ephraim Chambers (c. 1680-1740), best remembered today as the root out of which grew the Encyclopédie of Diderot and D’Alembert. First published in 1728 in two volumes, the entry relating to Paper is not in the main sequence, but is to be found in the lengthy unpaged Addenda placed at the end of the second volume. Since it takes up six pages, it is a conspicuous afterthought. The description of the papermaking process, obviously written from first-hand observation, is concise, but valuable, and has been heavily drawn on by English-language bibliographers, such as Philip Gaskell.

The invention of the Hollander beater at the end of the Seventeenth century aroused immense interest at the time. It was described therefore in a number of contemporary technical treatises, of which the earliest is the Vollständige Mühlen-Baukunst by architect Leonhard Christoph Sturm, published in Augsburg in 1718. It includes copper-plate illustrations both of the traditional stamping mill and of the newer Hollander beater, though of course the discussion limits itself to the beating process and does not deal with papermaking as such. Leendert van Vuuren, Jacob Polly, and Cornelis van Vuuren, Groot Volkomen Moolenbock, Amsterdam, Johannes Covens & Cornelis Mortier, 1734-36, 2 vols., likewise explain how to harness a Hollander beater to a wind-powered mill (the same illustration as is taken up subsequently in Lalande).

All these early treatises were eclipsed, however, by what was originally conceived and written as a technical report, but has since become a keystone in the history of papermaking scholarship. First published in 1761, L’Art de faire le papier, signed by one of the most important scientists and astronomers of the day, Joseph Jérôme Lefrançois de Lalande (1732-1807; the name comes with alternative orthographies), is by far the most reader-friendly account of the process produced at any time in history, and is also famous for its magnificent, albeit not always accurate, illustrations [5]. The work had a complex genesis over a period of some seventy years. It began with a manuscript commissioned by Jean Anisson in 1693, entitled ‘Description d’une des plus considerables papeteries d’Auvergne’ by artist Paul Sevin (1650-1710). These drawings became the basis of plates engraved in 1698 by Louis Simonneau (1654-1727), intended for the project of the “Description des arts et métiers” undertaken by what at the time was the Académie Royale des Sciences. The next step was a paper, read to the Academy in 1706, entitled ‘Description de l’art de la papeterie’, by academician Gilles Filleau Des Billettes (c. 1634-1720), whose contribution is mentioned by Lalande in his introduction. Another fifty years passed, however, before Lalande took up the baton and wrote a treatise that was above all an explanation of the Hollander beater employed at the L’Anglée factory in Montargis, though the older 1698 plates, showing the traditional stamping mill and papermaking at the vat, were recycled and integrated with further plates dated 1761, showing above all the new sort of beater.

The other text that dominates Eighteenth-century writing about papermaking is the entry ‘Papeterie’ in the Encyclopédie ou Dictionnaire raisonné des sciences, des arts et des métiers, Paris, 1751-72, more generally known by its editors Diderot and D’Alembert [5]. Authorship of the entry has been attributed to perhaps the most important figure to have worked on the project after the two editors, Louis-Jacques Goussier (1722-99), who was also responsible for the drawings behind the wonderful copperplate images, while the related entry on ‘Papier’ is by Louis de Jaucourt (1704-80). What has not yet been properly explicated is the relationship of the ‘Papeterie’ entry, which appeared in 1765, to Lalande, while the illustrations also show several debts to the example of a few years earlier. It cannot be a coincidence that both of them base their accounts on the same paper factory, known as L’Anglée or Langlée, just outside Montargis, at Châlette-sur-Loing. Begun in 1739 and completed in 1741, the complex represented the state of the art and was fitted with the new Hollander beaters. In 1852 the building was sold and the following year was converted into a rubber-processing plant by the American businessman, Hiram Hutchinson (1806-69), who however only spent a year in France before turning the factory over to his son, Alcander. On the night of 23-24 September 1869 most the structure was destroyed by a disastrous fire, which left only one of the original wings intact, and meant that the factory had to be entirely rebuilt. Initially named the Compagnie du Caoutchouc Souple, the Hutchinson firm produced rubber-coated garments and boots, but from the 1890s won fame as a producer of bicycle tyres and remains France’s only manufacturer in this field. The Châlette-sur-Loing site was quitted in 1967 for a new purpose-built factory at Ingrandes; after a number of years of neglect and abandon, the buildings were recovered and are now the Hutchinson Centre de Recherche. On Google Maps the rectangular-shaped basin dug for the original paper factory, which drew water from the nearby canal, is still clearly visible.

Not exactly a description of the papermaking process, but still an absolutely fascinating book, especially if you can view the original is the Versuche und Muster ohne alle Lumpen oder doch mit einem geringen Zusatze derselben Papier zu machen, self-published in six volumes in Regenberg between 1765 and 1771, by Jacob Christian Schäffer (1718-90), theologian, pastor, scientist, botanist, inventor and various other things. The increasing scarcity of rags by the end of the Eighteenth century led Schäffer to experiment with other sorts of vegetable fibre, including poplar, hops, and moss. What is remarkable about the books, but also accounts for their rarity, is that they include sample sheets of each and every type of paper (so it is also the first known example of a paper sample book). Although the use of alternative fibres did not take off at the time, the experiments pointed a long way into the future.

In 1762 a Dutch scholar, Gerard Meerman (1722-71), offered a prize of twenty-five ducats for whomever could establish the date of the earliest rag-based paper. Answers arrived from all over Europe and in 1767 were published as Gerardi Meerman et Doctorum Virorum ad eum Epistolae et Observationes De Chartae Vulgaris seu Lineae Origine, edidit ac praefatione instruxit Jacobus van Vassen, Hagae-Comitum, apud Nicolaum van Daalen, 1767. This work is notable also for containing the first published reproduction of watermarks [23]. The two images – a crown and a bull’s head – are far from being a faithful representation of the originals, but they would make an amazing T-shirt!

The Dizionario delle arti e de’ mestieri by Francesco Griselini, published in Venice from 1768 to 1778, as the title implies, is little more than an Italian paraphrase of the Encyclopédie. The entry on the ‘Cartera’ in the fourth volume (1769), rather engagingly, or disgracefully, depending on how you see it, renders technical terminology straight from the French rather than seeking out the true Italian equivalent. For example, the workmen at the vat are described as the tuffatore and the distenditore, from the French plongeur and coucheur, rather than the correct Italian terms, lavorente and ponitore. The illustrations are also copied straight out of the Encyclopédie.

A little beyond the terminus of the end of the Eighteenth century is an exceptionally interesting publication that has been much used by subsequent generations of paper scholars, interested in Oriental methods, or the Arts, métiers et cultures de la Chine, published in Paris in 1814. Based on the observations of Catholic missionaries François Xavier Dentrecolles (1664-1731) and Pierre Martial Cibot (1727-1780), it includes twelve hand-coloured plates, and has its own undeniable charm [2].

To conclude by returning to the absence of a hierarchical text mentioned above, papermaking lacks an equivalent of Moxon’s Mechanick Exercises on the Whole Art of Printing (1683-84) or Fertel’s La science pratique de l’imprimerie (1723) for the printing world, i.e. a manual written not for bibliographers or scholars, but to give a professional in the field an overview and appropriate guidelines. Or rather, such texts were written, but for the world of mechanical papermaking, and for the most part they are technical manuals about the workings of now obsolete machinery. The one partial exception is Robert Henderson Clapperton and William Henderson, Modern Paper-making, a book with a complicated history: first published in London, Ernest Benn, 1929, with distinct impressions in April and June; with a second edition in Oxford, Basil Blackwell, 1941, followed by a third with the same imprint in 1947; the work was substantial expanded in what is confusingly called a “Third edition”, signed only by Clapperton, published again by Blackwell in 1952. Although most of the book is about the machinery and the practical running of a mill, there are interesting pages about the sorting of rags, in a period before artificial fibre destroyed the centuries-old basic material of papermaking.